NK Performance and Racing

AFR 238CC LS3 ENFORCER AS CAST (Select Options)

AFR 238CC LS3 ENFORCER AS CAST (Select Options)

Couldn't load pickup availability

AFR's 238 LS3 Enforcer Cylinder heads feature our Permanent Mold “As-Cast” Technology surfaces on the intake runners, exhaust runners and combustion chambers that allows for extremely accurate and repeatable port location/performance. The AFR 238cc LS3 Enforcer is the first Enforcer casting with 100% AFR design. With a smaller valve and port, this head outflows your OE LS3 casting, offering greater performance potential. This budget friendly head is perfect for your OEM engine operating below 6300 RPM. They come fully assembled with the identical components found in our higher end CNC ported cylinder heads; such as PAC Racing springs, viton valve seals, machined bead valve locks (not stamped), hardened spring seats, and our one piece 8mm 21-4N/21-8N Stainless Steel valves. They are available without any parts for the DIY. Sold as a single piece, 2 are required per engine. Please see footnotes for additional information.

| Basic Package Components | |

| 100% As Cast Intake, Exhaust, and Combustion Chambers | |

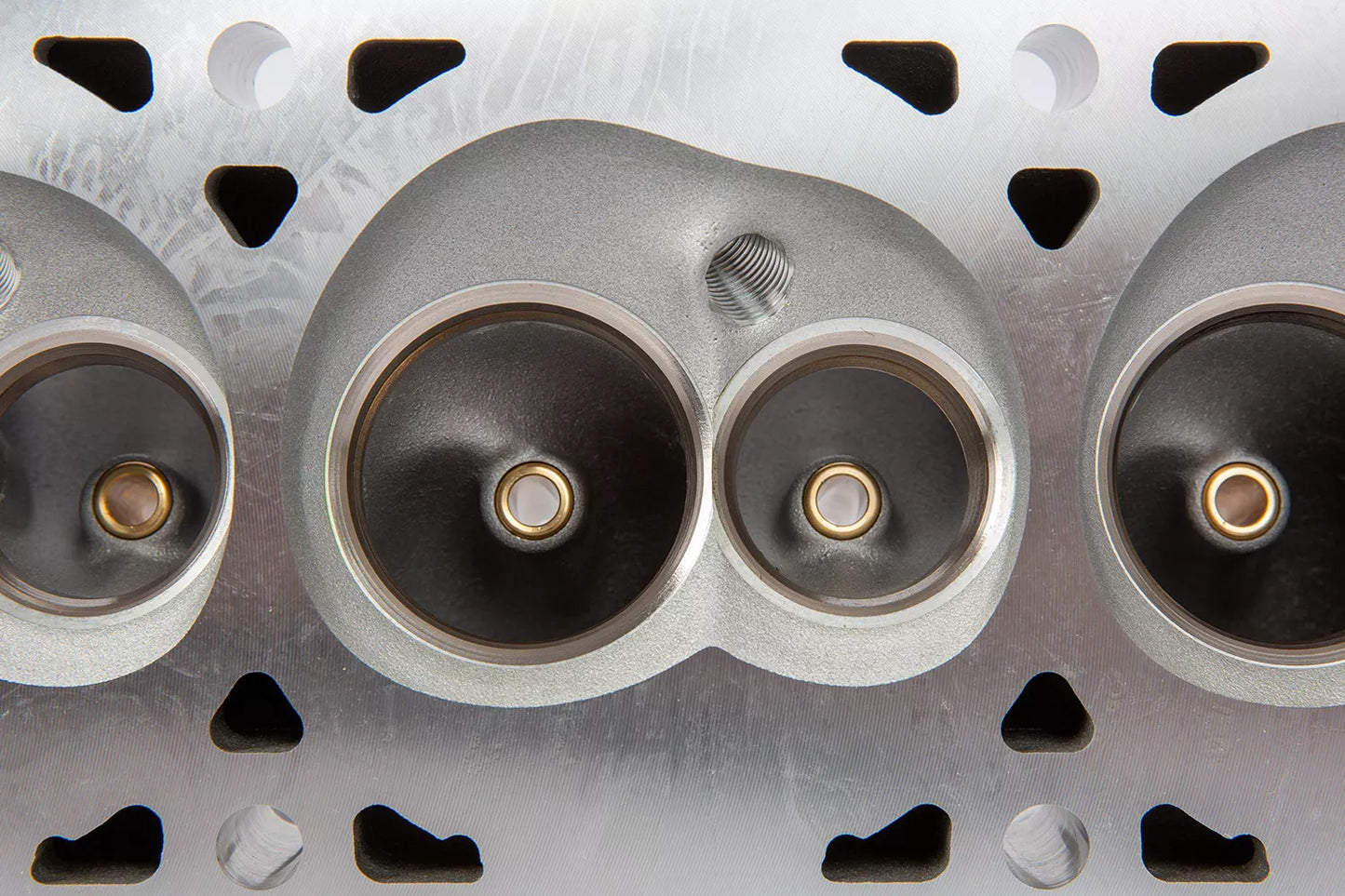

| Competition 5-angle Valve Job | |

| 8mm Bead Lock Intake Valve, 2.080" x 5.200" Overall Valve Length | |

| 8mm Bead Lock Exhaust Valve, 1.600" x 5.205" Overall Valve Length | |

| PAC Racing Spring 1.270" OD Hydraulic Roller Dual Valve Spring, 155 lbs. on seat, .650 maximum lift, Max RPM 7000-7200 | |

| 7° Steel Retainers 1.245" O.D x .880" I.D x .655" I.D | |

| 7° Bead Lock Valve Keepers | |

| Viton Valve Seals .600" O.D x .495" I.D | |

| Hardened Valve Spring O.D Locator 1.380" O.D x .570" I.D | |

| Rocker Rail Stand |

AFR #6040

|

| 238cc LS3 As Cast Flow Chart | |||||||

| .200 | .300 | .400 | .500 | .550 | .600 | .650 | |

| Int | 157 | 229 | 276 | 307 | 315 | 308 | 308 |

| Exh | 112 | 152 | 182 | 204 | 209 | 215 | 217 |

Test conducted at 28" of water (pressure) on Superflow 1020

Bore Size: 4.060", intake 3/4" radius plate exhaust, 1 3/4" curved pipe

| Recommended Components: | |

| Intake Port Gasket |

Factory GM or Aftermarket

|

| Recommend Rockers - OEM w/ trunion upgrade Yella Terra 6733 w/ 5132 Valve Cover gasket. |

Scorpion 1162

|

| Exhaust Port Gasket |

GM #12558573

|

| Head Gasket |

Cometic 4.160 Bore Size

|

| Head Bolts (04+), ARP 134-3610 | |

| Head Studs (04+), 2004 & Later Blocks ARP #234-4317, Pre 2004 Blocks ARP #234-4316 | |

| Head Bolt Washers, Manley | |

| Suggested Manifold |

FAST 92mm or 102mm

|

| Spark Plug Starting Range |

NGK TR55

|

| Pushrods: Longer than Stock (see instructions for details) | |

| Specifications & Features: | |

| Material |

A356 Aluminum

|

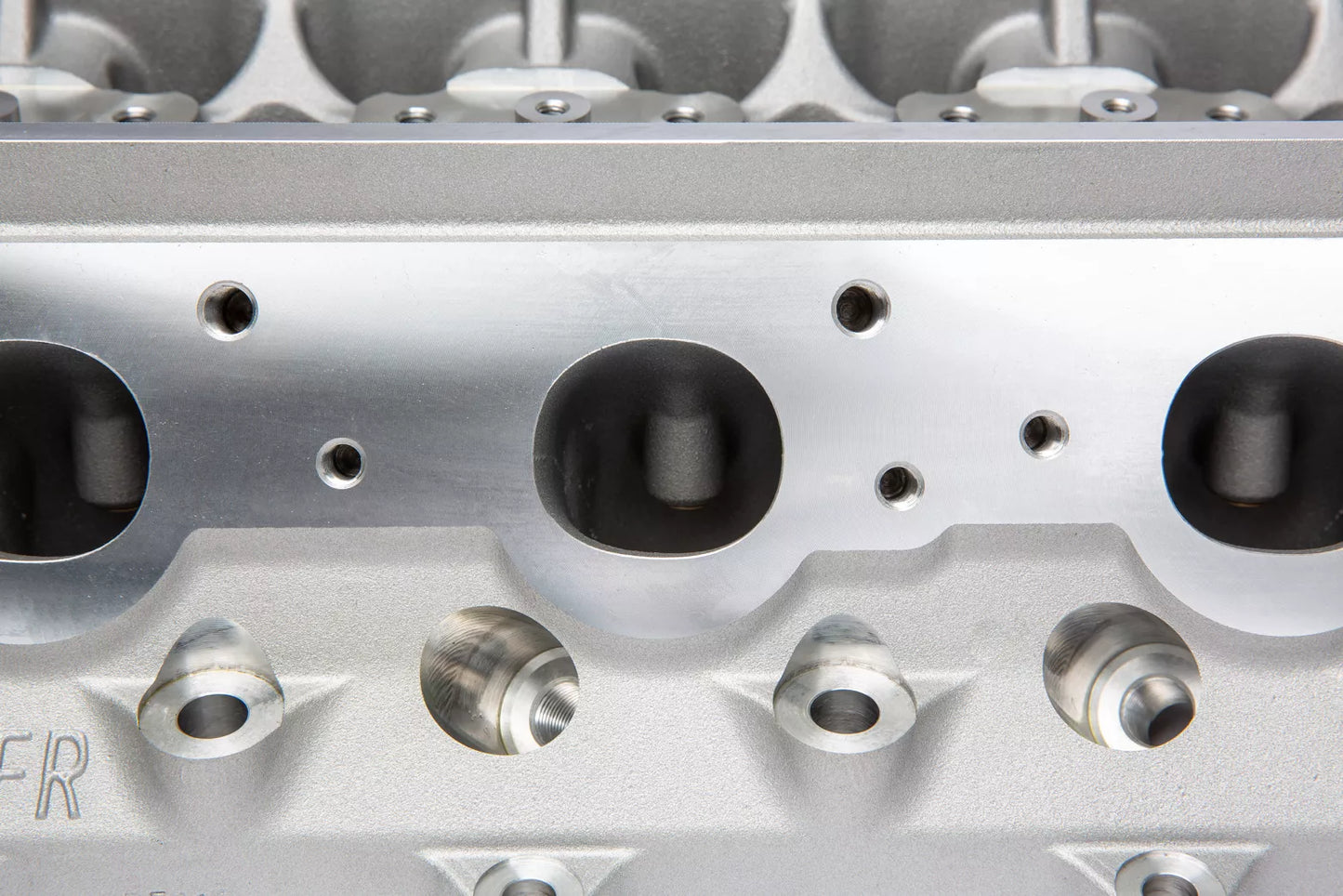

| Intake Port Volume |

238cc

|

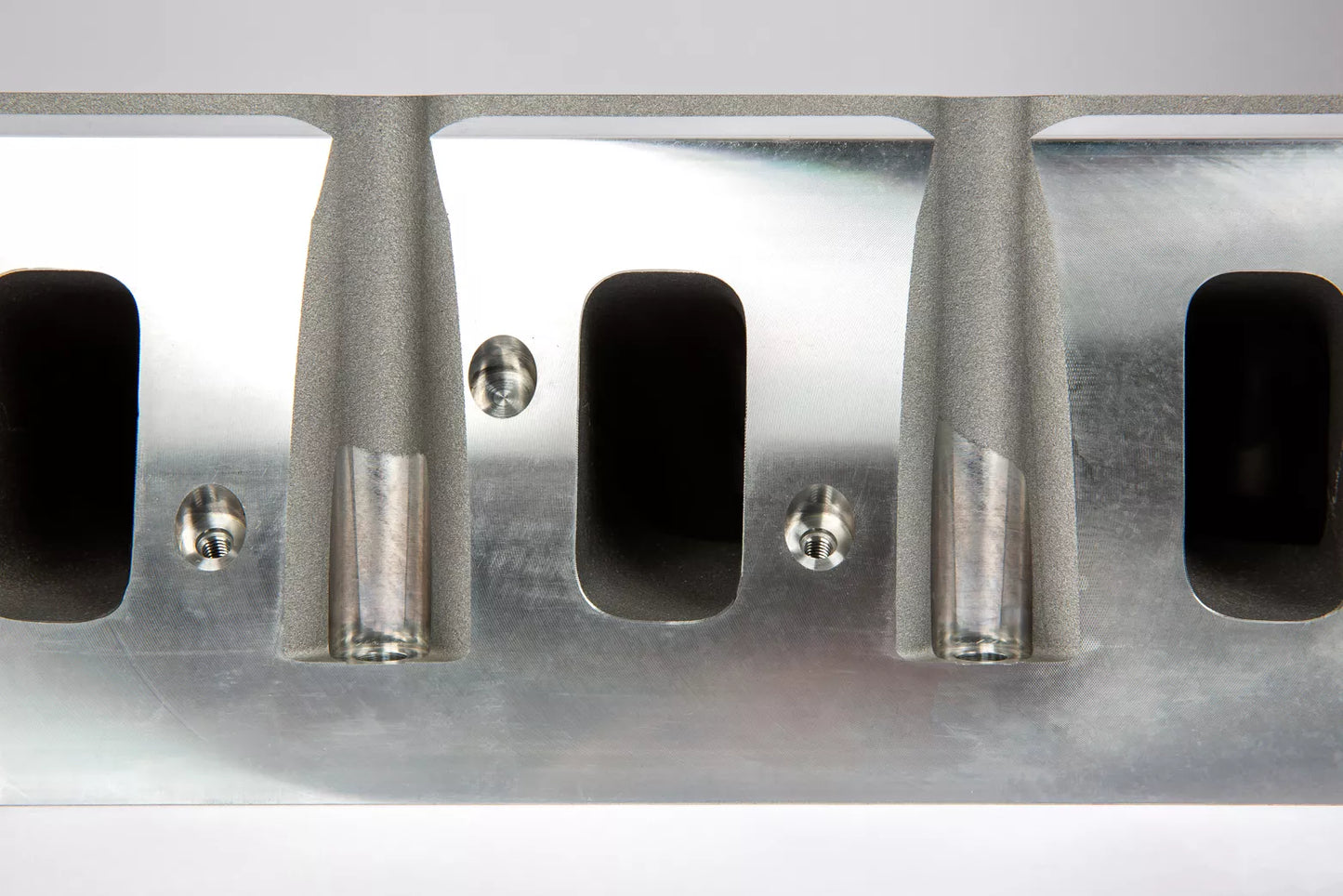

| Intake Port Dimension |

2.540"H x 1.190"W x 7/16° Radius

|

| Intake Port Location |

Stock

|

| Exhaust Port Volume |

92cc

|

| Exhaust Port Dimension |

1.500" H x 1.740" W

|

| Exhaust Port Location |

Stock

|

| Combustion Chamber Size |

72cc

|

| Valve Cover Bolt Pattern |

Center Bolt

|

| Valve Angle |

12°

|

| Valve Spring Pocket Diameter |

1.490" O.D

|

| Max Valve Spring Pocket Machining |

1.510" O.D

|

| Warning: Do not machine spring pad any deeper. | |

| Deck Thickness |

.750"

|

| Minimum Bore Diameter |

4.000"

|

| Flat Mill - 65cc chamber |

.006" per cc 62cc Maximum

|

| Minimum Cross Sectional Area |

|

| Spark Plug Dimensions |

14mm x .750" w/ Tapered or Gasket Seat

|

| Carb EO# |

|

-

AFR LS3

- Stock GM Rocker Arms - GM Rocker Arms are not designed/engineered to accommodate aftermarket cams or higher spring pressures. At a minimum AFR recommends using Bushing Trunion Kit. Other available options are aftermarket kits from Yella Terra, Scorpion or Hardland Sharp. Without the proper parts you will experience accelerated guide wear.

-

General Recommendations for AFR Cylinder Heads:

- Bar Codes - Please keep the bar code & paperwork shipped with your head, these contain all the specs for your heads when calling AFR.

- High Volume/Pressure Oil Pumps - If you are using a high volume or high pressure oil pump it can submerge the valve seals in oil causing smoking or oil consumption. Your block manufacturer or engine builder can recommend oil restrictions to the top end/valve train components.

- Pushrods - Different length pushrods might be required, always check pushrod length. Check pushrod clearance with heads placed on the block before final assembly. Larger pushrods will not fit without clearancing and is not recommended since some areas are very thin. AFR recommends the use of .120" thick-wall pushrods.

- Mills - Flat or angle mills could affect flow numbers and might require a thicker intake gasket.

- Stud Girdles - Due to many available factory OEM and aftermarket style/variations your existing stud girdle may not fit (AFR heads require AFR Stud Girdles)

- Boosted/Nitrous Applications - We strongly recommend considering Inconel exhaust valves and AFR's optional heavy duty intake valve for power adder applications. Since boosted or nitrous oxide applications accelerate RPM quickly, additional spring pressure is required. We strongly recommend upgrading your valve springs or increasing your valve spring pressures since boost pressure on the valve reduces spring tension. For example, 15lbs boost on a 2.125 OD valve reduces the springs closed seat pressure by approximately 40-45lbs.

- All MARINE Applications - We strongly recommend Inconel exhaust valves & also offer a hard anodized coating to slow the effects of corrosion. Please see note on guide clearance below.

- Valve Guide Clearance - Your AFR Heads come with proper guide clearance (.0012"-.0016") for most applications. Boosted/Nitrous or marine applications might require additional clearance and it is the customer's responsibility to verify proper clearance in these applications.

- Valve Springs - Forced induction, nitrous oxide and cams with aggressive ramp rates may require additional spring pressure. We offer optional valve springs for these types of applications. AFR also recommends the use of billet cam cores and short travel Hydraulic Roller lifters which tolerate higher spring loads. Please don't hesitate to contact us directly if you question which spring is correct for your application.

- AFR Titanium Valves - Might require lash caps and different length pushrods. Titanium valves are coated, do not grind valves because it removes the protective coating.

- Piston to Valve - AFR assumes no responsibility for damage if the end user builds an engine without properly verifying he has enough piston to valve clearance (depth and radial clearance both checked). We recommend a minimum depth of .080" on the intake valve and .100" on the exhaust with a radial clearance of .020" minimum around the perimeter of each valve. Clay is recommended to visually verify both depth as well as radial clearance. Just checking depth is not enough, the position of the valve pocket must also be addressed. It is the customers responsibility to verify proper piston to valve clearance.

- CNC Porting - Occasionally a 100% CNC ported head might have a very small area left "as cast", this in no way affects performance.

- Shaft Mount Rockers - Shaft mount rockers might require additional clearance for proper pushrod fitment. Do not clearance the push rod area as the wall is .060" thick. If you use Jesel Shaft Mounts, AFR only recommends their Pro Series.

- Comp Cams Pro Magnum Rockers - Typically these rocker arms do not clear a 1.500" O.D retainer. A lash cap is required to space up the rocker arm.

- Spring Installation - To ease installation with 1.550" O.D or larger springs, 12 pt head bolt or studs are recommended for extra clearance. Beveled or ground washers might be needed (ARP #200-8504 comes with smaller O.D and doesn't need to be ground)

- Valve Spring Installed Heights - AFR valve spring installed height spec is +/- .015 which is the smallest shim available for adjustment.

- Rocker Arms - Use full roller rocker arms, roller tip rockers with stock style bodies are NOT recommended.